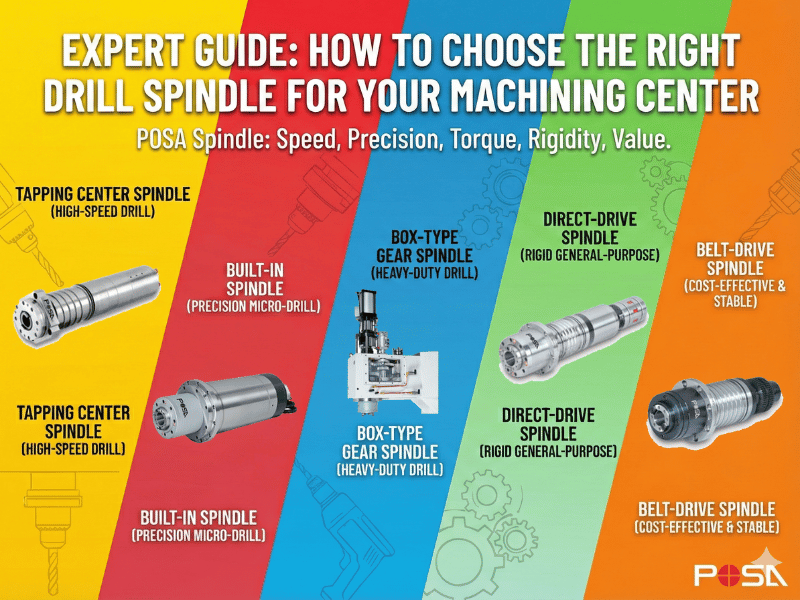

Expert Guide: How to Choose the Right Drill Spindle for Your Machining Center

In the world of CNC machining, the term "Drill Spindle" is often used broadly. However, experienced machinists know that not every spindle is optimized for the same type of drilling. Are you drilling thousands of micro-holes in aluminum, or boring large-diameter holes into cast iron? The "best" drill spindle depends entirely on your specific application.

At POSA Spindle, we understand these nuances better than anyone. Since 1994, we have dedicated ourselves to the manufacturing and development of high-end spindles. Through our strict standard operating procedures (SOP) and assembly within constant temperature clean rooms, we ensure that every spindle we produce meets the highest standards of precision and stability.

To help you maximize efficiency and tool life, we have categorized POSA’s machining center spindles by their ideal drilling capabilities. Here is your guide to selecting the right technology for your needs.

1. Tapping Center Spindles: The High-Speed Drill Spindle

Best For: Mass production, 3C electronic parts, automotive die-casting.

When your cycle time is measured in seconds, you need agility. POSA’s Tapping Center Spindles are the ultimate high-speed drill spindles. Designed for rapid acceleration and deceleration, they minimize the non-cutting time during drilling cycles.

- Why it works: The low inertia design allows the spindle to reach top RPM instantly.

- Drilling application: High-volume hole making (up to Ø12mm) where chip-to-chip time is critical.

2. Built-in Spindles: The Precision Micro-Drill Spindle

Best For: Mold & die finishing, medical components, aerospace parts.

For high-precision applications requiring small diameter tools (often under 1mm), vibration is the enemy. POSA’s Built-in Spindles (motor integrated directly into the shaft) serve as the perfect precision drill spindle. Thanks to our rigorous dynamic balancing and run-in tests, these spindles operate with exceptional smoothness.

- Why it works: With no transmission gears or belts, vibration and run-out are virtually eliminated.

- Drilling application: Micro-drilling and deep-hole drilling where tool run-out must be near zero to prevent breakage.

3. Box-type Gear Spindles: The Heavy-Duty Drill Spindle

Best For: Energy industry, heavy machinery, railway components.

Speed isn't everything; sometimes you need raw power. If your operation involves large U-drills or spade drills, you need a Heavy-Duty Drill Spindle. POSA’s Box-type Gear Spindles utilize a robust transmission gearbox to multiply torque at lower RPMs.

- Why it works: The gear mechanism provides massive torque output that direct motors cannot match at low speeds.

- Drilling application: Large diameter drilling in tough materials like steel, titanium, and cast iron.

4. Direct-drive Spindles: The Rigid General-Purpose Spindle

Best For: General mold making, precision parts, automotive components.

The Direct-drive Spindle is the versatile all-rounder. By coupling the motor directly to the spindle shaft, it offers a balance of speed and rigidity. It serves as an excellent rigid drill spindle for shops that handle a wide variety of jobs.

- Why it works: The direct coupling eliminates backlash, providing better rigidity than belt drives and higher torque than some built-in models.

- Drilling application: Standard drilling and tapping in various metals, offering high surface quality.

5. Belt-drive Spindles: The Cost-Effective & Stable Spindle

Best For: General job shops, standard component machining.

Sometimes, the classic solution is the best solution. The Belt-drive Spindle remains a popular choice as a reliable drill spindle due to its simplicity and distinct mechanical advantage: vibration damping.

- Why it works: The rubber belt naturally absorbs minor vibrations from the machining process, protecting the spindle core.

- Drilling application: General-purpose drilling where cost-efficiency and ease of maintenance are priorities.

Why Choose POSA Spindle?

Selecting the right spindle configuration is the first step, but choosing the right partner is equally important.

For over 30 years, POSA Spindle has stood for quality and technological advancement in the lathe and machining center spindle industry. Our commitment goes beyond manufacturing; we utilize rigorous run-in tests and strict quality control in our temperature-controlled assembly facility to ensure every unit performs flawlessly.

Whether you need high-speed efficiency or heavy-duty torque, POSA has the perfect Drill Spindle solution for your machining center.