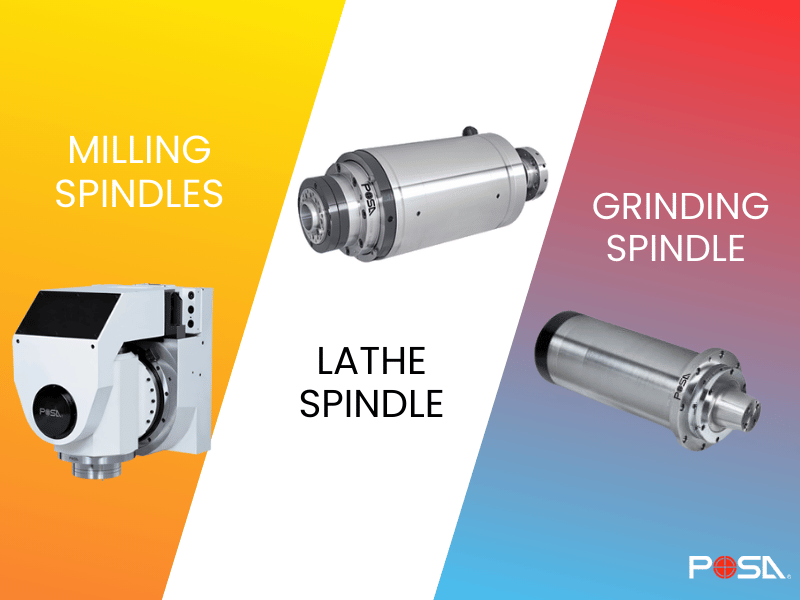

In modern manufacturing, spindles play a central role in achieving precision, efficiency, and surface finish across a wide range of machining processes. However, not all spindles are created equal. Depending on whether you're operating a lathe, grinding machine, or milling center, the spindle design, performance characteristics, and application considerations vary significantly.

In this article, we’ll compare lathe spindles, grinding spindles, and milling spindles, highlighting their functions, key differences, and how to choose the right type for your application.

What Is a Lathe Spindle?

A lathe spindle is the heart of a CNC lathe or turning center. It holds and rotates the workpiece, allowing the cutting tools to shape it while the part spins. Lathe spindles are typically designed for high torque and rotational speed, and they must maintain excellent rigidity to withstand axial and radial loads.

Key Features:

- Hollow or solid design to accommodate bar feeding

- High-speed rotation with torque emphasis

- Support for chucking systems (hydraulic, pneumatic, manual)

- Often includes C-axis for positioning in multi-tasking lathes

Typical Applications:

- Shaft and cylindrical part turning

- Thread cutting

- Drilling and boring along the center axis

What Is a Grinding Spindle?

A grinding spindle powers the abrasive wheel used in grinding machines. Unlike cutting processes, grinding involves high-speed rotation with lower torque, and the spindle must deliver extremely high precision with minimal runout.

Key Features:

- Ultra-high rotational speed (often over 60,000 RPM)

- Extremely low vibration and runout (less than 1 micron)

- Air/oil lubricated hybrid or ceramic bearings

- Often sealed or motorized for minimal maintenance

Typical Applications:

- Surface and cylindrical grinding

- Tool and cutter grinding

- Semiconductor wafer thinning

- Mirror-finish or ultra-precision machining

What Is a Milling Spindle?

A milling spindle is found in vertical, horizontal, or 5-axis CNC machining centers. It holds rotating cutting tools such as end mills, drills, and face mills. Milling spindles must balance rotational speed, power, and rigidity, especially when machining tough materials or during heavy chip loads.

Key Features:

- Taper interface (BT, HSK, ISO, CAT)

- Automatic tool change (ATC) compatibility

- High torque for low-speed heavy cutting

- Internal cooling and air/oil mist lubrication

- Speed ranges from 6,000 to 24,000+ RPM depending on use

Typical Applications:

- Mold & die machining

- Structural component milling (e.g., aerospace, automotive)

- Multi-axis surface contouring

- High-speed pocketing and drilling

Comparison Table

| Feature | Lathe Spindle | Grinding Spindle | Milling Spindle |

|---|---|---|---|

| Main Function | Rotates workpiece | Rotates grinding wheel | Rotates cutting tool |

| Speed Range | Moderate–High (3,000–6,000 RPM) | Very High (20,000–100,000+ RPM) | Variable (6,000–24,000+ RPM) |

| Torque | High | Low | Medium to High |

| Precision | Moderate | Ultra-precise | High |

| Typical Bearings | Angular contact / roller | Air/oil hybrid / ceramic | Roller / angular contact |

| Cooling | Air / oil / liquid | Air / oil mist | Liquid / internal air |

| Tool/Work Interface | Chuck, collet, bar feeder | Grinding wheel arbor | Tool holder (HSK, BT, CAT) |

How to Choose the Right Spindle for Your Application

Choosing the right spindle depends on:

- Type of machining: Turning, grinding, or milling

- Required speed and torque

- Precision and surface finish expectations

- Workpiece material

- Cycle time and production volume

For example:

- If you're grinding hardened steel to sub-micron tolerances, a high-speed grinding spindle with ceramic bearings is essential.

- For heavy-duty turning of large shafts, a powerful lathe spindle with through-hole bar feeding is ideal.

- If you're machining aluminum molds, a high-speed milling spindle with tool change capability improves efficiency.

POSA's Expertise in Spindle Technology

At POSA Machinery, we specialize in the design and manufacture of precision spindles for CNC lathes, grinding machines, and machining centers. Our product range includes:

- High-torque lathe spindles with C-axis control

- Ultra-high-speed grinding spindles with hybrid ceramic bearings

- Customizable milling spindles with built-in motors and ATC support

With decades of experience and ISO-certified production, we offer tailored solutions to meet the specific needs of your machines and your industry.

Conclusion

Each spindle type—lathe, grinding, and milling—has distinct performance characteristics tailored to specific machining tasks. Understanding these differences is critical for machine tool builders, integrators, and end users alike. Choosing the right spindle ensures better machining precision, longer tool and machine life, and improved productivity.

Need help choosing the ideal spindle for your machine?

Contact POSA Machinery today for expert consultation and world-class spindle solutions tailored to your manufacturing goals.